|

|

PIT & LAGOON TREATMENT

SEPTIC

TANKS and CESSPOOLS

FAST

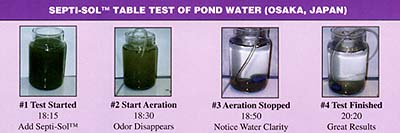

RESULTSSEPTI-SOL begins

to work immediately! Odors are diminished

within minutes after the initial use. There

is an immediate release of oxygen in solution

from water and organic materials containing

oxygen at a sufficient rate to cause a population

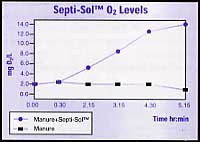

explosion in microorganisms.INCREASE

IN AVAILABLE OXYGEN

D.O.

(dissolved oxygen) levels of 4-6 fold are

often reported. With more oxygen available

for natural biological activity, odors are

quickly reduced or eliminated. Ammonia and

other gases are reduced or eliminated as

well. SEPTI-SOL quickly converts

anaerobic (without air) conditions into

aerobic (with air) conditions. Anaerobic

microorganisms are the gas producers. Once

these types of microorganisms are eliminated,

gases are eliminated. Instead of fermenting

(rotting), manure is degraded biologically.

Excess ammonia gas can reduce your daily

gain. Health of animals is improved which

results in higher profits for growers.

Iowa State University Test ResultsWASTE

TO VALUE

SEPTI-SOL

converts waste (manure) into a valuable

agricultural nutrient. Nitrogen present

in manure will be turned into single cell

protein, enzymes, natural antibiotics, free

amino acids and polypeptides that become

a natural organic nitrogen fertilizer in

a micro solid form. This end product serves

as an excellent soil conditioner adding

natural benefits like improved soil texture,

depth of water percolation, and better water

retention.

LAGOON

TREATMENTThe

major problems associated with animal lagoons

and the animal industry are the extensive

noxious odors and the accumulation of solid

manure due to the anaerobic status of lagoons

and litter areas. SEPTI-SOL and a

aerobic microorganism culture will eliminate

the odor problem and enhance the degradation

of solids.Noxious

odors disappear rapidly following the SEPTI-SOL

treatment with a significant improvement

observed within the first few minutes. In

many instances, this odor is simply intolerable

to the surrounding communities and may pose

an eventual health risk forcing closure

or relocation. The amount of product required

for a successful treatment varies, but is

cost effective. In many cases, it will actually

reduce the overall cost of operation. By

improving the environmental quality and

accelerating the rate of solid degradation,

the high cost of frequent lagoon clean-out

processes is eliminated. Many non-treated

odors and their resulting gases (ammonia),

cause disease and sickness with animals

and birds.Odors

may be attributed to many parts of a working

organization and waste flow. Prior to the

SEPTI-SOL treatment, there is usually

odor in the pens and barns, odor in the

drainage area to the lagoons, odor from

the ditches, odor from the washed-down and

recycled water, and odor from the lagoon.

SEPTI-SOL is capable of solving each

of these odor problems, and more.Some

operations have installed filtration systems

for recycling water and have discovered

the incredible recycled water quality provided

by SEPTI-SOL, as well as the reduced

required maintenance of the filtration system.

This not only translates to significant

water savings, it also diminishes the total

water volume in surrounding lagoons and

eliminates the substantial discharge into

waste streams improving environmental quality.Most

SEPTI-SOL treatment users have recognized

the hidden benefits of their newly treated

water. SEPTI-SOL treated water can

be used for irrigation purposes. In fact,

SEPTI-SOL treated water applied to

any soil, actually improves

the soil condition; helping to normalize

pH, improve water percolation, improve water

retention, and improve crop yields. NORMAL

SEPTI-SOL RESULTS1.

Reduction of large air bubbles (methane)

from the bottom of the lagoon which are

replaced by small (sometimes very small)

carbon dioxide bubbles with a low moisture

mist over the lagoon on non-windy mornings

and evenings. LAGOON

TREATMENTThe

major problems associated with animal lagoons

and the animal industry are the extensive

noxious odors and the accumulation of solid

manure due to the anaerobic status of lagoons

and litter areas. SEPTI-SOL and a

aerobic microorganism culture will eliminate

the odor problem and enhance the degradation

of solids.Noxious

odors disappear rapidly following the SEPTI-SOL

treatment with a significant improvement

observed within the first few minutes. In

many instances, this odor is simply intolerable

to the surrounding communities and may pose

an eventual health risk forcing closure

or relocation. The amount of product required

for a successful treatment varies, but is

cost effective. In many cases, it will actually

reduce the overall cost of operation. By

improving the environmental quality and

accelerating the rate of solid degradation,

the high cost of frequent lagoon clean-out

processes is eliminated. Many non-treated

odors and their resulting gases (ammonia),

cause disease and sickness with animals

and birds.Odors

may be attributed to many parts of a working

organization and waste flow. Prior to the

SEPTI-SOL treatment, there is usually

odor in the pens and barns, odor in the

drainage area to the lagoons, odor from

the ditches, odor from the washed-down and

recycled water, and odor from the lagoon.

SEPTI-SOL is capable of solving each

of these odor problems, and more.Some

operations have installed filtration systems

for recycling water and have discovered

the incredible recycled water quality provided

by SEPTI-SOL, as well as the reduced

required maintenance of the filtration system.

This not only translates to significant

water savings, it also diminishes the total

water volume in surrounding lagoons and

eliminates the substantial discharge into

waste streams improving environmental quality.Most

SEPTI-SOL treatment users have recognized

the hidden benefits of their newly treated

water. SEPTI-SOL treated water can

be used for irrigation purposes. In fact,

SEPTI-SOL treated water applied to

any soil, actually improves

the soil condition; helping to normalize

pH, improve water percolation, improve water

retention, and improve crop yields. NORMAL

SEPTI-SOL RESULTS1.

Reduction of large air bubbles (methane)

from the bottom of the lagoon which are

replaced by small (sometimes very small)

carbon dioxide bubbles with a low moisture

mist over the lagoon on non-windy mornings

and evenings.

2. Reduction in lagoon odor and at point

of waste water irrigation. Once the aerobic

system is completely established and the

sludge has been degraded, the odor will

rapidly dissipate.

3. Reduction of solids on the surface and

sludge under the surface. The liquefying

of solids will continue to the depth at

which the mixing is effective. If the aerator

is capable of mixing to the entire depth,

then solids will completely disappear except

for the newest raw waste.

4. Nitrogen present in manure will be turned

into single cell protein, enzymes, natural

antibiotics, free amino acids, and polypeptides;

becoming a natural organic nitrogen fertilizer

in a micro-solid form.

5. The SEPTI-SOL treated water, when

applied to soil, becomes a potent microorganism

and soil conditioner capable of improving

soil conditions, improving water percolation,

water retention, and crop yields. OUTLINE

OF TREATMENTApply

a diluted solution of water and SEPTI-SOL

at the rate of 50:1 over the slats, water

surface, or the the surface of the manure

storage facility. Using the chart below,

apply the required amount of SEPTI-SOL

every three to four months or as often

as needed. GENERAL

SUMMARY OF TEST RESULTSThrough

extensive testing, we have been able to

determine that SEPTI-SOL is an extremely

cost effective solution to many of the problems

associated with manure wastes generated

from various industries. After treating

manure pits and lagoons with SEPTI-SOL,

there is an increased release of oxygen

in solution from water and organic materials

containing oxygen at a sufficient rate to

cause a population explosion in microorganisms.

In

the IOWA STATE UNIVERSITY of SCIENCE and TECHNOLOGY

testing report: DO (dissolved oxygen) levels

of 2.3 were dramatically increased to 13.7

in a short period of time. (This is an increase

of almost 6 fold using a ratio of 1:20,000

(SEPTI-SOL and Manure).In

the NORTH IOWA COLLEGE testing report: A 70 day trial

period using SEPTI-SOL resulted in

a 5 inch reduction in solids. Pit solids

on Feb. 24 measures 20 inches; pit solids

on May 6 measured 15 inches. Amazingly,

during the test period, additional new waste

was continuously introduced into the testing

environment.In

the BELMOND LABS testing report: Nitrates in the manure

were reduced by 37%. Nitrates in the control

measured 239 and nitrates in the SEPTI-SOL

treated sample measured 150.In

the second BELMOND LABS testing report: Of the 19 Amino Acids

tested during the profile, 18 amino acids

were increased when SEPTI-SOL was

used. GENERAL

SUMMARY OF TEST RESULTSThrough

extensive testing, we have been able to

determine that SEPTI-SOL is an extremely

cost effective solution to many of the problems

associated with manure wastes generated

from various industries. After treating

manure pits and lagoons with SEPTI-SOL,

there is an increased release of oxygen

in solution from water and organic materials

containing oxygen at a sufficient rate to

cause a population explosion in microorganisms.

In

the IOWA STATE UNIVERSITY of SCIENCE and TECHNOLOGY

testing report: DO (dissolved oxygen) levels

of 2.3 were dramatically increased to 13.7

in a short period of time. (This is an increase

of almost 6 fold using a ratio of 1:20,000

(SEPTI-SOL and Manure).In

the NORTH IOWA COLLEGE testing report: A 70 day trial

period using SEPTI-SOL resulted in

a 5 inch reduction in solids. Pit solids

on Feb. 24 measures 20 inches; pit solids

on May 6 measured 15 inches. Amazingly,

during the test period, additional new waste

was continuously introduced into the testing

environment.In

the BELMOND LABS testing report: Nitrates in the manure

were reduced by 37%. Nitrates in the control

measured 239 and nitrates in the SEPTI-SOL

treated sample measured 150.In

the second BELMOND LABS testing report: Of the 19 Amino Acids

tested during the profile, 18 amino acids

were increased when SEPTI-SOL was

used.

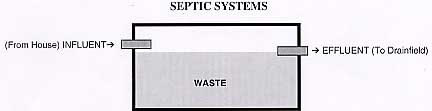

SEPTIC

SYSTEM TREATMENTSEPTI-SOL

accelerates the decomposition of animal

and human waste while reducing or eliminating

odors. Drain pipes carry waste from you

home to a septic tank or cesspool under

your yard. A septic tank is normally made

from metal or concrete and is completely

enclosed. bacteria breakdown waste in the

tank to prevent solids from entering the

drain field. Most other products contain

harsh chemicals that destroy the necessary

bacteria in your septic tank. Septi-Sol

is a natural biological solution that will

enhance the natural bacteria activity.  Septic

systems usually fail when lateral lines

become blocked from solids building up,

causing an overflow and back-up into the

house. SEPTI-SOL applied via the

commode begins clearing the system immediately

by breaking down solids usually within 24

hours. Septic

systems usually fail when lateral lines

become blocked from solids building up,

causing an overflow and back-up into the

house. SEPTI-SOL applied via the

commode begins clearing the system immediately

by breaking down solids usually within 24

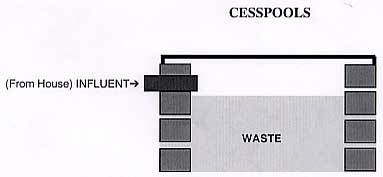

hours. Cesspools

are built with open walls of stone or concrete.

Aerobic bacteria, which need a supply of

fresh air to survive, break down waste that

enters the pool. Liquid seeps into the ground

surrounding the cesspool through the open

walls. SEPTI-SOL will ensure that

aerobic bacteria survive and aid in the

digestion of the waste solids helping to

eliminate clogging and odor. Cesspools

are built with open walls of stone or concrete.

Aerobic bacteria, which need a supply of

fresh air to survive, break down waste that

enters the pool. Liquid seeps into the ground

surrounding the cesspool through the open

walls. SEPTI-SOL will ensure that

aerobic bacteria survive and aid in the

digestion of the waste solids helping to

eliminate clogging and odor.

Back

to the top> |

|